Occupational Health and Safety

Basic approach and policy

The Group is committed to occupational health and safety as an important theme.

Occupational Health and Safety & Health Promotion Policy

The T. Hasegawa Group recognizes that ensuring the occupational health and safety and promoting the well-being of all employees is a vital responsibility. Accordingly, we have established the following policy on occupational health and safety and health promotion.

- We regard occupational health and safety of our employees, including temporary employees and contractors, as the highest priority in the Group’s business, and ensure a safe and comfortable working environment.

- We comply with laws, regulations, and rules related to occupational health and safety.

- Based on the recognition that employee health is the basis of everything we do, we support the maintenance and promotion of the physical and mental health of our employees.

- We set goals and action plans for occupational health and safety and health promotion, review them periodically, and strive to continuously improve the work environment.

- We provide opportunities for consultation and dialogue with our employees and seek their consultation and input on occupational health and safety and health promotion.

- We provide ongoing training for employees on occupational health and safety and health promotion.

This occupational health and safety and health promotion policy, as described above, was approved by the Group’s Board of Directors on November 28, 2024.

Governance and risk management

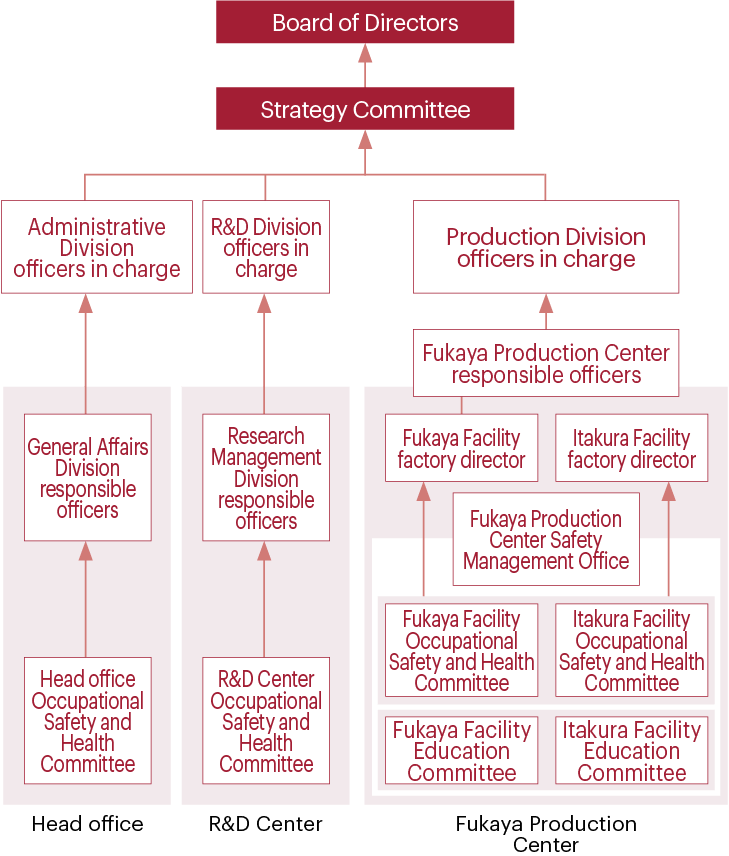

Promotion system

We have established Occupational Safety and Health Committees at each site and are implementing measures to prevent personal hazards and health problems among our employees. We conduct risk assessments at workplaces once a year. We carry out careful risk assessments not only at existing operations, but also at the start of new operations, such as when new equipment is installed, to ensure that safety is a priority. In addition, regular reports on incidents are made to the Board of Directors twice a year. Whenever a serious incident occurs, it is reported to the Board of Directors in order to discuss the response to take.

Health and safety management system chart

Strategies

Increase in business opportunities

- Increased job application rate and employee retention rate

- Increased production efficiency as a result of improving the work environment

We work to improve workplace sanitation by placing top priority on ensuring occupational safety and disaster prevention. At each site, the Occupational Safety and Health Committee develops activity policies and plans, and it works on workplace environment safety and security and disaster prevention activities in compliance with the Fire Service Act and other laws and regulations related to safety and disaster.

System for hazard identification, risk assessment, and incident investigation

With the goal of eliminating occupational accidents, each site holds a monthly Occupational Safety and Health Committee meeting. The Committee deliberates and shares information on safety and health activities based on the analysis of factors and countermeasures for accidents and occupational injuries, as well as the situation of employees on sick leave. The Safety and Health Committee, established in accordance with the Industrial Safety and Health Act, includes managers and employees at each business site, labor union representatives, and industrial physicians. Furthermore, the division head of each workplace identifies workplace hazards, assesses risks, and implements appropriate countermeasures while listening to input from employees. In particular, they communicate the dangers of handling chemical substances and their toxicity to all employees while regularly measuring the organic solvent concentration in the work environment to assess its effect on the health of employees.

In the event of a serious accident or occupational accident, a company-wide Accident Investigation Committee is established. We have established a framework for quickly reporting accidents to the Committee, investigating causes, developing recurrence prevention measures, and implementing the measures. The Fukaya Production Center, which is our production factory, established a Safety Management Office in April 2023. It has been working to improve the workplace environment to prevent occupational accidents, which is its most important issue. We ensure that all employees check and follow the rules.

In accordance with the Occupational Health and Safety Management System Guidelines of the Ministry of Health, Labour and Welfare, we are operating and promoting an Occupational Health and Safety Management System for the Fukaya Production Center, which was established internally.

To make sure we do not forget the industrial accident at the Itakura Facility that occurred on September 15, 2022, we have designated September 15 as Safety Day. With the aim of raising awareness of occupational safety, we promoted the development of a safe work environment and occupational safety education for all employees.

System to improve a series of processes

Until FY2023, the company-wide Environment and Safety Committee audited environmental and occupational safety issues at plants for prompt improvements and compiled them in Corrective Action Reports and other documents. However, starting from FY2024, the Occupational Safety and Health Committee at each site will take the lead in conducting audits on occupational safety.

System for employees to report on danger

At the Fukaya Production Center, employees provide information on near misses and improvement requests during morning meetings and safety roundtables at each workplace so that all members can understand the potential danger there. The Occupational Safety and Health Committee also deliberates and takes risk reduction measures, which are deployed to other workplaces. In addition, hazard prediction activities (KY activities) engaged in work that may cause accidents and occupational injuries are conducted at each workplace to enable employees to foresee hazards in their own work and take preventive measures.

Providing training on safety and health to employees

The Fukaya Facility holds safety and health-related skills training for all employees (training upon hiring, training upon reassignment, periodic risk education, etc.) in an effort to raise employee awareness of safe work practices. Our employees also actively participate in outside lectures to obtain the qualifications necessary for work.

Employee health care

Prevention of overwork and interviews with industrial physicians

We properly monitor the working hours of all employees, including managers, and confirm whether they wish to be interviewed by an occupational physician if they work long hours. We also encourage them to be aware of their physical health.

Health checkups

Employees who are 35 years of age and older can receive a full medical examination at the Company’s expense, and we encourage them to undergo health checkups actively.

Stress checks

Stress checks are conducted once a year to promote employee awareness of stress and improve the work

environment. We recommend employees with elevated stress levels to talk with an industrial physician.

In addition, the results of the group analysis are reported at the strategy meeting, and a debriefing

session is held for each division, after which each division formulates and implements improvement measures.

Provision of health-related information

- Distribute a monthly insurance newsletter published by the health insurance association.

- Industrial physicians check the results of health checkups and promote medical checkups to employees who need to take the necessary measures.

- Information on health issues and work environment from industrial physicians is posted on the Company’s bulletin boards.

Indicators and targets

The Group has set a target of zero occupational accidents for the period from FY2024 to FY2028. In FY2024, six occupational accidents were reported. Each case was investigated by the Safety and Health Committee at the respective site, with root causes identified and recurrence prevention measures formulated. These findings were shared company-wide via our internal intranet. We will continue to strengthen our efforts to enhance occupational health and safety.

In FY2024, our occupational accident severity rate was 0.06 (0.0598), which is 0.02 points lower than the industry average for the manufacturing sector (0.08).

We also manage key indicators such as the number of work-related fatalities, number of lost-time injuries, number of non-lost-time injuries, lost-time injury frequency rate, occupational accident severity rate, and occupational illness frequency rate.

For more details, please refer to the T. Hasegawa Group ESG Data Book (PDF) .