Innovation

Basic approach and policy

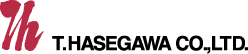

The T. Hasegawa Group is working to find unique flavors and fragrances by developing them and identifying new aroma components through technologies for creating fragrances, analyzing, synthesizing, and developing ingredients. The Group is also working to streamline and improve the efficiency of manufacturing methods in consideration of the environment and resource conservation. Responding to customer needs and potential demands while resolving social issues will lead to new product development and new business exploration from the perspectives of responding to health consciousness, contributing to foodtech, providing health and enrichment, and finding solutions for an aging society. Through flavors and fragrances, we aim to realize rich and healthy lifestyles and contribute to the creation of a sustainable society.

Relation with stakeholders

Customers

We provide the ideal flavors and fragrances for customer needs by providing high-quality and high value-added products.

Examples of customer success cases

We integrate marketing data and sensory evaluation data to visualize customer issues and make proposals that support product development. We have also developed a unique communication tool called Aroma Value Visualizer®, which visualizes the value of flavor and fragrance by combining physiological response measurements such as salivary gland activity and technologies, and Aroma Rainbow®, which expresses fragrance in color. We use these techniques and tools to share awareness of our customers’ apparent as well as latent issues, so that we can respond accurately to customer requests.

Natural environment

We are developing flavors and ingredients that enhance taste and help supplement food resources whose supply has become unstable due to the impacts of climate change and other factors. In synthetic chemical studies, we aim to develop environmentally conscious ingredients by continuing to reduce the amount of solvent used and replace toxic substances with improved manufacturing processes while taking into account green chemistry. Specifically, we are using “The IFRA Green Chemistry Compass,” published by the IFRA, to evaluate the conformity of our chemical processes to green chemistry based on the 12 articles related to green chemistry. This clarifies issues to be addressed and enables more efficient improvement activities. We contribute to reducing the thickness of PET bottles and saving resources through the development of ingredients that enhance the flavor of natural raw materials and other ingredients that supplement the sensation of carbonation, which will lead to the protection of biodiversity and food resources. As part of our own Circular Economy initiative, we have been experimentally cultivating lemongrass in Koumi-machi in 2023 using botanical residue compost from our affiliated company, Koumi Compost.

Joint research partners: universities and research institutes

Through knowledge sharing and opinion exchange, we strive to absorb cutting-edge research and improve our technology.

Governance and risk management

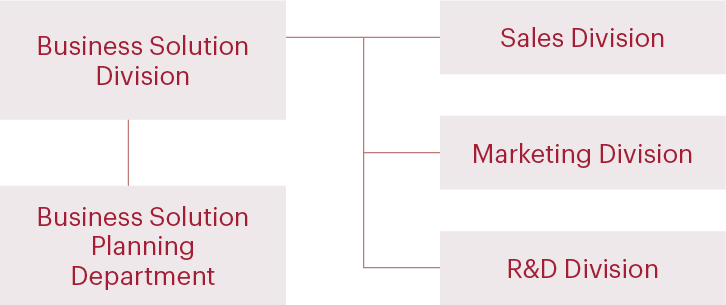

The Business Solution Division, which was established in 2020, is strengthening collaboration between the Sales, Marketing and R&D Divisions. Under the strategy of the Business Solution Planning Department, we will systematically work to provide our customers with high-quality and high value-added products while aiming to help solve social issues and achieve sustainable growth. In addition, the R&D Center serves as the backbone of our flavor, fragrance, and ingredients development.

The Flavor R&D Center, the Fragrance R&D Center, and the Technology R&D Center pursue research in their respective specialized fields and collaborate with each other to combine their achievements, thereby strengthening our research and development capabilities.

Organization chart

(1)Fragrance Division

The domestic market for cosmetic fragrances is now in a mature stage, and competition among domestic and overseas fragrance manufacturers is intensifying. In addition, we are also facing rising raw material prices due to changes in the resource environment. Under these circumstances, we have been working to continue improving our perfumery technology while placing the highest priority on safety, quality, and environmental issues. Furthermore, we have been conducting research and development in cooperation with sales and marketing. Utilizing our perfumery, analysis, and synthesis technologies, in FY2024, we continued to work on developing highly perfected fragrances with long-lasting and diffusive characteristics, proposed new product forms in terms of application, accurately identified customer needs based on preference and marketing surveys, and conducted research that led to cost reductions. As a result, many of our products have been adopted by customers both domestically and internationally.

As we continue promoting globalization, we are also further strengthening our technical support based on market research in overseas countries and regions while making every effort to acquire new customers.

Our Chinese subsidiary, T. Hasegawa (Shanghai) Co., Ltd., is strengthening sensory evaluation and research on applications in addition to its Perfumery R&D Division in order to respond to diversifying customer needs.

(2)Flavor Division

As consumer lifestyles and preferences continue to diversify, competition among manufacturers and retailers has intensified, resulting in shorter product life cycles. The Group conducts customer-oriented research and development to meet the increasingly diverse and fast-changing needs of our customers. For example, we have developed authentic-tasting flavors, new flavor ingredients created using advanced extraction and processing technologies, and flavor systems that combine taste-enhancing components such as richness boosters. We actively present these innovations to our customers and have responded to their needs through these tailored solutions. Furthermore, we conducted research and development on new applications of flavors, which resulted in the adoption of our manufactured goods in major new products by domestic and international customers in FY2024 as well.

In addition, as we aim for globalization, we are developing flavors that meet the unique tastes of each country and researching their applications to our customers’ products. While strengthening technical support for our overseas subsidiaries and distributors in various countries, we have steadily increased our customers’ adoption of our products.

The R&D Division of US subsidiary T. Hasegawa USA, Inc. has been expanding research on applications to customers’ products and has been successful in acquiring new customers.

Our Chinese subsidiary, T. Hasegawa (Shanghai) Co., Ltd., is enhancing its R&D capabilities and improving operational efficiency by fully leveraging the functions of the new research building completed in November 2023.

Our Malaysian subsidiary, T HASEGAWA FLAVOURS (KUALA LUMPUR) SDN. BHD, is continuing to strengthen the R&D system to expand the sales of compounded flavors across various Asian countries, in addition to its core product of powder seasonings.

(3)Basic R&D Division (common to Fragrance Division and Flavor Division)

①Research on synthetic flavors and fragrances

We have developed synthetic flavors and fragrances that characterize the aroma of our products while also improving manufacturing methods to streamline the manufacturing process of existing products and develop manufacturing methods for flavors and fragrances that consider environmental conservation (sustainability).

As an example, for one of the synthetic raw materials in production, we have switched from a process that uses raw materials from rare plants to an upcycled process that uses by-products from the flavors and fragrances industry.

②Research on natural products

We have developed an aroma analysis method using various aroma collection methods and the latest analytical equipment to improve the accuracy of analysis of trace aroma components, thereby clarifying the composition of aroma components in many natural products and applying it to the development of flavor and fragrance products. In addition, we have been developing flavor materials using the extraction technology to utilize natural flavors as well as natural pigments, natural antioxidants, and other functional food materials as naturally derived materials. We are also developing fruit-based processed products that incorporate flavors designed with consideration for the final manufacturing process. Based on these technologies, we offer original solutions unique to the Company.

③Research on sensory evaluation, physiological response, and biotechnology

We have developed original evaluation methods using measurement technologies in sensory evaluation and physiological response (head blood flow, muscle potential, etc.) and utilized them in our proposal activities. In addition, we conduct basic R&D on microorganisms and enzymes, as well as the development of flavor-enhancing ingredients through the application of these R&D results.

④Other research related to flavor and fragrance development

We continued R&D on high value-added flavor and fragrance products using emulsification, powdering, and other formulation technologies suitable for flavor and fragrance applications, as well as rationalization through process improvements in flavor and fragrance manufacturing. Furthermore, we developed new, safe food ingredients that meet the needs of the market.

Strategies

Increase in business opportunities

- Social challenges to which the Group can contribute with its technology

- Increasing interest and need for creating a sustainable society

- Possibilities of flavors and fragrances to create new value

Measures

- Sustaining R&D investments

- Proposing activities using marketing data and AI

- Speedy development: accurately identifying and rapidly responding to customer requests and latent needs

- Detailing responses to customers

- Responding to increased demand for alternative raw materials triggered by climate change

- Absorbing advanced technologies and knowledge through active exchange of views with universities and research institutes

We set KPI for maintaining and improving the ratio of R&D expenses to net sales and for continuing open innovation, and will promote the continuous development of new technologies in collaboration with universities, research institutes, and other organizations in order to strengthen our product development and proposal capabilities. In addition, we will further strengthen our organizational structure.

Development of an organizational structure

Collaboration between the Sales, Marketing and R&D Divisions to form the Business Solution Division has advanced, and the speed of responding to customers is accelerating. To achieve customer success, we have strengthened information sharing with reference to marketing data, technical materials and research results, with the aim of further promoting solution sales. We continue to focus on research and development to increase sales.

T. Hasegawa Group’s proprietary technologies

We introduce many of our proprietary technologies.

Please see

“Original

Technologies”

for details.

Product development and proposals

We offer proposals that integrate marketing data with sensory evaluation data. We also promote the active use of intellectual property, such as sensory evaluation data, to strengthen the linkage between compounding, analysis, and application and to develop new, unique products.

Development of an alternative to gum arabic

Gum arabic is a natural emulsifying agent derived from the bark of Acacia trees, commonly used in foods worldwide for its high emulsifying properties. However, the social and political instability in the major production regions of gum arabic has raised concerns about supply reliability. In response, we have developed a sustainable alternative with emulsifying and dispersion properties equivalent to gum arabic by combining widely used food-grade protein and polysaccharide materials through the Maillard reaction.

These research findings were presented orally under the title “Analysis of Emulsifying Properties of Protein/Polysaccharide Complexes Formed by the Maillard Reaction” at the 71st Annual Meeting of the Japan Society for Food Science and Technology, held from August 29 to 31, 2024, at Meijo University (Tempaku Campus, Aichi Prefecture).

External collaboration

To strengthen product development and proposals, we are striving to absorb cutting-edge research and improve technology through knowledge sharing and opinion exchange, and we are continuously promoting joint research with universities and research institutes.

Development of an orange juice alternative

We have been working on the development of an orange juice alternative by applying our emulsification technology for flavors, and have successfully created a proprietary ingredient (a patented emulsified flavor material currently under patent application). This new material has been shown to enhance the juiciness and mouthfeel of beverages, enabling product formulations that reduce the amount of orange juice used without compromising its flavor.

To verify the effectiveness of this ingredient, we conducted not only sensory evaluations by expert panels but also analytical assessments using precision instruments. The results confirming its juice-substitution capabilities were presented at the 33rd Annual Meeting of the Japan Soft Drink Association, held on October 8, 2024, at the Japan Education Center in Tokyo.

Due to rising prices and supply uncertainties surrounding orange juice caused by social conditions and climate change, our newly developed ingredient contributes to the stable supply and price stabilization of products that use orange juice.

* Some of the verification experiments were conducted as part of a joint research project with Yokohama National University.

Contribution to society

Responding to health consciousness

Bringing delicious taste to low-sugar, low-salt and low-fat foods

We develop ingredients that enhance sweetness, umami and saltiness in response to the development of products that pursue a “healthy and good taste” for customers. Furthermore, we also propose ingredients that add delicious flavor to food with reduced sugar and salt content. In addition, by developing products that impart a sense of fat and oil and a rich, full-bodied effect, we are proposing ingredients that add a sense of satisfaction to low-calorie, non-oil products.

Contributing to foodtech

Solution for the lack of food resources

As part of the development of flavors to replace depleting food sources, we also offer a flavor series that can replace savory natural raw materials and alternative compounded flavors for citrus essential oils. To address the shortage of vanilla beans, we are developing materials that can produce a vanilla taste even when the amount of vanilla beans is reduced by applying compounded flavor and the heat reaction technology. In addition, we have developed a compounded flavor based on aroma analysis. By combining that flavor with emulsified oils and fats, we propose an ingredient that complements the flavor of milk even when the amount of dairy ingredients used is reduced.

For plant-based food, which effectively reduces the environmental impact, we have Plant React®, an ingredient that adds the flavor and taste of animal products without actually using animals and contributes to reproducing the distinct flavor.

Koku Jyuwa®, which is generated by using the power of enzymes in natural vegetable fats and oils, contributes to reducing the use of oil and fat ingredients with supply concerns by imparting a rich, full-bodied effect to foods.

Providing health and enrichment

Bringing fragrance to living spaces and developing new technologies for skin care products

We are developing high value-added and long-lasting fragrance materials that can provide fragrance in situations where it is needed. We have also developed NANOLYS®, an innovative solution for all sensitive skin in the world.

For more information, please visit NANOLYS.

Development of a method to express the relationship between flavor and emotional concepts

In recent years, product development has increasingly emphasized emotional concepts such as moods, feelings, or imagined scenes (for example, a shampoo for moments of relaxation, or coffee to enjoy on a day off). Focusing on the emotional aspects of aroma, we explored the relationship between origin-specific flavor characteristics and emotional concepts, using single-origin coffee as a case study. We prepared coffee extracts using dark-roasted beans from four representative origins—Brazil, Ethiopia, Colombia, and Guatemala—and conducted (1) a detailed flavor evaluation by expert panels, and (2) an emotional evaluation by general consumer panels. Through integrated analysis of (1) and (2), we confirmed that specific emotions and situations are associated with particular flavor characteristics (for example, coffee perceived as comforting by consumers tended to have a sweet aroma). In this way, by combining flavor evaluations by aroma experts (expert panels) with emotional evaluations by consumers (general panels), we established a method for visualizing the relationship between emotional concepts and aromas/flavors based on data.

These research findings were presented as a poster under the title “Development of a Method to Express the Relationship Between Flavor and Emotional Concepts in Single-Origin Coffee: Connecting Flavor and Emotion” at the 2023 Annual Meeting of the Japanese Society for Sensory Evaluation, held on November 26, 2023, at Tokyo University of Agriculture (Tokyo). The presentation received the Society’s Excellent Presentation Award.

Solution for an aging society

Improving quality of life in hospitals and nursing homes

As a solution to various unpleasant odors in our daily lives, we research and investigate such odors themselves in detail and use the obtained data to develop fragrances that help reduce or eliminate them. In addition to developing masking materials for daily odors to improve the hospital and nursing care environment, we use near-infrared spectroscopy (NIRS) and develop Swallowing Map® as part of our efforts to facilitate eating and add good taste to nursing care food.

Indicators and targets

The Group uses indicators such as R&D expenses, number of patent applications, and number of joint research projects with external organizations.

In FY2024, the percentage of R&D expense was 7.7% (consolidated basis), and we conducted 14 joint research projects.

For more details, please refer to the T. Hasegawa Group ESG Data Book (PDF) .