Environmental Management

Basic approach and policy

We have established the Environmental Philosophy to clarify our stance towards environmental protection and have formulated the Environmental Safety Activity Policy and the Environmental Policy based on ISO 14001 in order to embody the philosophy.

Under various environmental policies, the Board of Directors holds overall supervisory responsibility for environmental management and promotes its implementation.

Environmental Philosophy

The T. Hasegawa Group recognizes that the important common issue facing all of humanity is to pass on this irreplaceable planet to future generations. As a comprehensive flavor and fragrance manufacturer, we give due consideration to environmental protection in all of our business activities.

Environmental Safety Policy

In addition to environmental protection, the Group also views security and disaster prevention, as well as chemical safety, as important corporate themes. As such, we incorporate these themes into our Environmental Safety Policy and engage in relevant activities.

Environmental Protection

- Promotion of energy conservation

- Reduction of GHG emissions

- Conservation of resources and water

- Promotion of effective waste utilization

- Odor countermeasures and environmental pollutant emissions reduction

- Strengthening of the environmental management system (EMS)

- Promotion of green purchasing

Security and Disaster Prevention

- Promotion of hazardous material safety measures

- Promotion of disaster prevention and safety measures

Chemical Safety

- Development of a chemical substance management system

- Promotion of chemical safety measures

ISO14001 Environmental Policy

As a comprehensive flavor and fragrance manufacturer involved in the production, research, and development of food flavors, cosmetic fragrances, synthetic flavors and fragrances, food additives, foods and cosmetic materials, the Fukaya Production Center and the R&D Center of T. Hasegawa Co., Ltd. recognize the importance of achieving harmony with the environment and aim to become companies that are trusted by society. To achieve this, we will conduct activities related to the environment in accordance with the following policies.

- Promote resource conservation, water conservation, and energy efficiency, and to contribute to the protection of the global environment

- Promote the reduction of greenhouse gas (GHG) emissions

- Promote the reduction and recycling of waste products.

- Promote coexistence with local communities by strengthening environmental management at applicable sites and surrounding areas and working to prevent pollution.

- Comply with air, water, and other laws and agreements related to the environment.

- Conduct internal audits, etc., to make continuous improvements to the EMS.

- Provide environmental education to all employees to improve their environmental awareness.

Information disclosure to customers

We disclose information via platforms such as the CDP, EcoVadis, and Sedex. We also respond to supplier surveys conducted by customers.

Environmental education for employees

We provide environmental education in a multifaceted approach as part of our efforts to improve environmental awareness among employees.

Training and information provision via the intracompany website

We post environment-related pages on our intracompany website and provide a Sustainability Report and other environmental information. Since FY2022, we have been providing e-learning classes on the basic knowledge of SDGs to all employees in Japan, including employees assigned to overseas offices (excluding employees who are absent for a long period of time).

In FY2024, we conducted a comprehension test after the session and achieved a response rate of 100%. We disclose the response results on the intracompany website in an effort to improve employees’ knowledge of sustainability.

Internal environmental seminars

The Environmental Safety Committee, Education Committee, etc., of each factory plan and hold seminars and study meetings on environmental issues. In FY2024, we held internal seminars and study sessions on a wide range of topics, including sustainability, communication with external stakeholders, the relationship between ISO 14001 and the SDGs, ESG-focused management, and carbon neutrality.

External environmental seminars

Employees involved in environmental safety work participate in professional seminars, lecture meetings, exhibitions, etc., in an effort to upgrade their environmental knowledge. In FY2024, we invited external lecturers to conduct training on water-related issues. We also participated in lectures on environmental technologies and attended exhibitions focused on environmental themes.

Internal education

New employees undertake adequate education and training when they join the firm. We also provide sustainability training as part of our courses for newly hired employees. In FY2024, we conducted training sessions on topics such as the SDGs, carbon neutrality, wastewater treatment, and environmental regulations.

Environmental education under the environment management system (ISO 14001)

The Fukaya Facility, the Itakura Facility, and the R&D Center conduct education and training in a planned manner as part of our ISO 14001 environmental management system (EMS). We also strive to promote environmental conservation by utilizing ISO 14001 message boards and the intranet at each workplace to share the environmental policy, environmental promotion posters, and other environment-related information.

Information disclosure to stakeholders

We post sustainability information (including this Report) on the Company website.

Governance and risk management

Promotion system

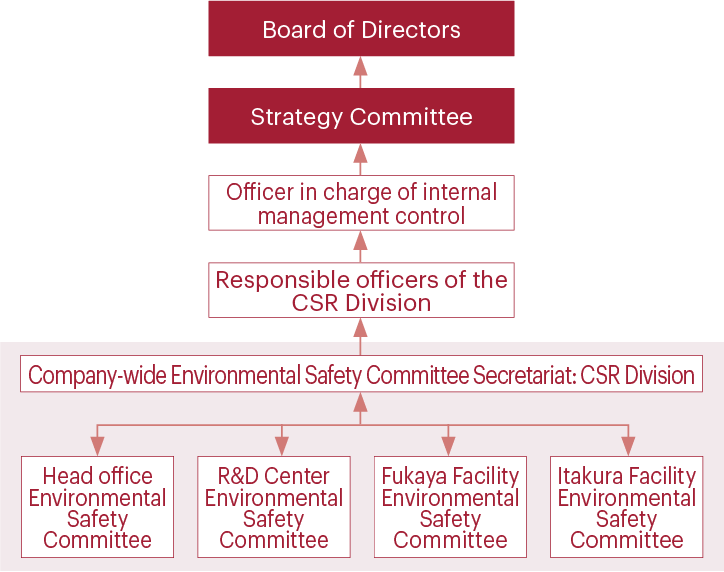

We have built and promoted an environmental safety management system in accordance with the Environmental Safety Management Rules. In addition, we have obtained the ISO 14001 certification, an international standard for environmental management systems, at our Fukaya Facility, Itakura Facility, and R&D Center. The Production Division and the R&D Division jointly check and manage that the systems are functioning effectively. The Board of Directors holds overall supervisory responsibility for environmental management and, as necessary, receives reports from the chairperson of the company-wide Environment and Safety Committee to fulfill its oversight role.

Environmental safety management structure

Environmental safety management structure chart

1) Company-wide Environmental Safety Committee

- The committee is chaired by the officer in charge (or deputy officer in

charge) of internal management control overseeing the CSR Division, which serves as the secretariat.

It is composed of the chairpersons, vice-chairpersons, and other members of the Environment and Safety

Committees at each site.

It deliberates and decides on company-wide policies and activity plans related to environmental protection and safety measures. - The Committee receives reports on environmental safety activity plans, activity results, etc., from each site and coordinates activities from a company-wide perspective.

- The Committee selects auditors of environmental safety audits (environmental protection in addition to security and disaster prevention) and conducts annual audits at each site.

2) Environmental Safety Committee of each site

- We have established an Environmental Safety Committee at our head office, R&D Center, Fukaya Facility, and Itakura Facility. It is chaired by the factory director, etc., and held at these sites, excluding the head office, every month.

- We promote activities related to environmental protection as well as security and disaster prevention by establishing specific activity plans and targets in accordance with the activity policy determined by the company-wide Environmental Safety Committee.

3) CSR Division

- The Division develops and promotes basic policies on CSR and the SDGs.

- This Division is responsible for the overall management of environmental safety activities.

- The Division operates the company-wide Environmental Safety Committee as a secretariat and formulates and manages the progress of the non-fossil energy conversion plan.

- The Division manages environmental safety audits as a secretariat, and compiles and reports the results to the Strategy Committee.

- The CSR Division discloses sustainability-related information through our website and Sustainability Report. In addition, it periodically reviews the disclosed information.

Environmental management system based on ISO 14001

In 2001, the Fukaya Facility and the Itakura Facility obtained an ISO 14001 environmental management system

(EMS) certification from the Japanese Standards Association and have since conducted relevant activities.

Note that the current certifying body is DNV Business Assurance Japan Co., Ltd. The Production Division

(Fukaya Facility and Itakura Facility) has a particularly large environmental impact compared to other

divisions of the Company. Furthermore, the Division works on continuous improvement by implementing the PDCA

cycle, which is a core concept of the ISO 14001 system.

In June 2012, we added the R&D Center to the

scope of certification in an attempt to strengthen the efforts of reducing environmental impact from the

product design phase.

The Suzhou Facility in China has been certified since 2015. As of FY2024, four of the ten production and R&D sites of the Group have acquired ISO 14001 certification (the ratio of ISO 14001-certified sites is 40%).

Internal audits based on ISO 14001

An internal audit is conducted in accordance with the internal program as prescribed in the Environmental

Manual.

When issues are identified, we take corrective actions promptly and share them with the related

divisions to ensure continuous improvement.

Environmental safety audits by the company-wide Environmental Safety Committee

Since 1997, the Environmental Safety Committee has been conducting audits related to environmental protection and safety measures.

From 2008 onwards, we reorganized our auditing framework into three categories to conduct more detailed checks: Environmental Protection Audits, Security and Disaster Prevention Audits, and Occupational Safety and Health Audits. We select expert auditors for each audit category. They check for compliance with environmental laws, the status of activities, and the management status at relevant facilities while issuing an improvement recommendations report for matters that need to be enhanced. In response, the site to be audited creates an improvement plan for the issues that were pointed out and implements the improvements after reporting to the company-wide Environmental Safety Committee.

Since FY2024, Occupational Health and Safety Audits have been conducted mainly by the Health and Safety Committee of each site.

After deliberation by the company-wide Environment and Safety Committee, the audit results are reported to the Strategy Committee and, if necessary, to the Board of Directors for deliberation and reporting to the directors for their supervision. In FY2024, audits were conducted at each site in August, and the audit results were reported at the Strategy Committee in October.

Strategies

Increase in business opportunities

- Response to social needs brought about by climate change.

Measures

- We will thoroughly comply with laws and respond to risks.

- We will solve environmental issues in accordance with the CSR Policies and incorporate them into our sustainable growth strategy.

Related measures

- The Strategy Committee considers and decides on environmental targets from a long-term perspective.

- The company-wide Environmental Safety Committee manages the progress of policies and promotes awareness among the entire Group.

- We ensure that measures against global warming are taken (reduction of energy consumption and GHG emissions through the activities of the Environmental Safety Committee, effective use of resources and waste products through resource conservation, and composition of waste products).

- We continue to join the Global Compact Network Japan, CDP, EcoVadis, and Sedex and maintain transparency through information disclosure on the platforms.

- We expand transactions with customers by ensuring traceability.

- We develop, propose, and sell products that accelerate innovation and contribute to solving social issues.

Information disclosure to stakeholders

We disclose the T. Hasegawa Group’s ESG initiatives through platforms such as CDP, EcoVadis, and Sedex, while promoting issue identification and continuous improvement efforts. We also respond to supplier surveys from business partners as needed. In addition, based on the disclosure recommendations of the TCFD and TNFD, we conduct risk and opportunity analyses related to climate change and natural capital, and disclose the relevant information. We also publish sustainability-related information (including the Sustainability Report, ESG Data Book, and GRI Standards Content Index) on our website as appropriate.

Environmental accounting

To promote our environmental conservation activities efficiently and effectively, we implement environmental

accounting with reference to the Ministry of the Environment’s Environmental Accounting Guidelines.

For more details, please refer to

the T. Hasegawa Group ESG Data Book (PDF)

.

Indicators and targets

We promote group-wide environmental management using indicators such as energy consumption, GHG emissions

(Scopes 1, 2, and 3), and the effective waste utilization rate.

For more details, please refer to

the T. Hasegawa Group ESG Data Book (PDF)

.